MODMAX delivers a new standard in modular construction using manufacturing quality precision, innovation and attainability. From multifamily homes to duplexes, hospitality, and small-scale communities, we cater our model to builders, general contractors, investors and real estate developers. Our turnkey approach to modular construction supports each project partner past the with a team that includes general contracting, transport, construction management, and resources into one cohesive, tech-forward solution backed by first-class service.

At MODMAX, based in Fayetteville, TN, we are transforming the future of housing through state-of-the-art modular manufacturing. Specializing in duplexes, fourplexes, and other essential “missing middle” housing types, we deliver scalable, cost-effective, and energy-efficient homes tailored to the needs of today’s homeowners, developers, and multifamily operators. Our mission is to empower clients to build smarter and faster without compromising quality—fostering vibrant, connected communities while reducing construction timelines and development costs.MODMAX is your trusted contract factory for modular solutions.

MODMAX’s 21st century modular construction process delivers a precise manufacturing “off-site” approach to building. When you consider the benefits of modular construction, you must look at all the individual factors which push the traditional mindset of “stick” building into the modern age:

Our purchasing, assembly, inspections and installation process is done in the same manufacturing assembly process for each home or unit. We employ skilled tradesman year-round and train each of our teams consistently and stay up to date on the cutting-edge materials, tools, and equipment.

Working in our controlled, climate-controlled environment reduces job site rain days, site issues, safety concerns, and tradesman coordination. We reduce the coordination and supervision burden on a general contractor which reduces costs for projects.

Modular construction in our facility allows developers to work in parallel with sitework construction to schedule delivery of full complete homes or units in a matter of months, instead of years, increasing the time to stabilize a community and increase investment returns.

With MODMAX’s modular manufacturing approach, the project is delivered with finish framing, plumbing, electric, HVAC all installed and ready to “Plug and Play” at the project site. This benefit reduces the amount of skilled tradesman and supervision needed to complete the project. All state and local building inspections are completed using 3rd party inspectors at our modular facility on a consistent weekly basis. Each individual unit gets thoroughly inspected, tested and approved prior to leaving our facility.

Our process involves ordering materials for each project at negotiated prices. We order production materials at a consistent, ‘Just-In-Time’ approach in a controlled, locked and 24/7 monitored facility with 360-degree cameras. Your investment in us as a partner to deliver your project means we ensure you are receiving a safe and secure facility on which to build in.

Our process involved the rigorous architecture plan review and approval with 3rd party “off-site” Construction review. Applicable compliance with International Residential Code (IRC) for one-and two-family dwellings, ADU’ or International Building Code (IBC) for multi-Family and commercial structures, is used for each plan set approval. Our certified inspections are then conducted per individual state requirements at our modular facility during the assemble process (100% inspection of construction.)

Our design–build system ensures total quality control, faster timelines, and lower costs — all under one roof. From precision design to factory-built completion, each unit moves through our streamlined production line and arrives on site ready for seamless installation.

The process begins with identifying and securing land for development. Our team is able to assist and conduct a site feasibility review to ensure the land is suitable for modular construction, evaluating access, zoning, and utilities.

We work with you to align project budgets and pro MODMAX duct solutions to meet your needs. ModMax can assist in providing preliminary budgets, cost savings models, and estimated timelines to support funding approvals.

Our modular experts work with your team to design efficient, scalable floor plans tailored to your site and market—whether multifamily, hospitality, or missing middle housing—all optimized for offsite construction.

Once designs are finalized, your team will be ready for permitting and coordinate with the local jurisdiction. A scope of work is defined for all parties involved, including developers, general contractors, and suppliers.

Modular units are built at our controlled facility, ensuring higher quality, reduced waste, and faster turnaround. Each module undergoes quality checks at every stage of production. Our builds are inspected and follow all city and state requirements.

A licensed general contractor handles all site work—foundation prep, module setting, exterior finishes, utility hookups, and final inspections. MODMAX supplies a clear scope of work to keep everyone aligned.

Upon factory completion, modules are safely transported to the project site. Your team will manage logistics and coordinate timing with the on-site team for seamless delivery and installation.

Once construction is complete, a final walkthrough is conducted with your general contractor to confirm all work meets specifications and local code. The project is then handed off to the owner or operator, ready for occupancy.

Build-to-Invest (B2I) is MODMAX’s scalable investment model which assists investors, builders, general contractors and developers to maximize the value of compact land parcels. Through smart density strategies and modular efficiency, Build-To-Invest (B2I) delivers turnkey multi-family properties with high-performance materials, with faster timelines, lower upfront costs, and greater market readiness.

Key Benefits of B2I:

Ready to Discuss your Project?

MODMAX Build-To-Invest (B2I) development scale solution turns underused land into high-yield investments – fast. Designed for small developers and real estate investors, B2I combines smart density with modular speed to unlock the full value of compact lots. The result? Turnkey rental properties with lower upfront costs, faster timelines, and higher returns — ready to hit the market in record time.

Unlock tricky urban lots and overlooked land parcels with pre-permitted, high-density models.

Maximize density and ROI on small or irregular lots with modular speed and scale.

Build clean, Attainable housing near campuses or job hubs — quickly and at scale.

Deliver high-quality workforce housing for families, seniors, and essential workers.

Partner on modular solutions to tackle housing shortages with speed and cost-efficiency.

Launch boutique hotels, extended stays, or ADU-style rentals with faster time-to-market

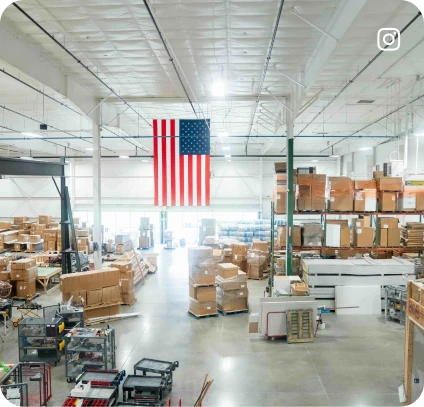

At MODMAX, every unit is built with factory-grade precision and digitally tracked from concept to completion. Our 85,223 sq ft facility runs a high-speed production line that reduces delays, cuts waste, and delivers consistent quality — every time. With our integrated digital platform, developers get real-time updates, seamless design integration, and transparent project oversight — all in one place.

Modular construction reduces overruns through predictable timelines, streamlined workflows, and fixed-factory pricing, helping you build smarter for less.

Our digital platform keeps you in control — track schedules, costs, and key milestones with full transparency from concept to completion.

Every module is factory-built under tight quality control, delivering consistent workmanship, structural integrity, and repeatable excellence at scale.

Off-site manufacturing reduces waste, limits weather delays, and minimizes neighborhood disruption — accelerating delivery while lowering environmental impact.

Ready to Discuss your Project?

MODMAX is powered by builders, investors, and innovators who believe modular is more than a method — it’s a movement.

CEO and Founder

CO-Founder & President

Director of Operations

Engineering

Ops & People Coordinator

Controller

Production Manager

Every project we deliver is a partnership — and our clients say it best. Here’s what developers, investors, and community leaders are saying about working with MODMAX.

Executive Director, Fayetteville-Lincoln County Industrial Development Board

Whether you’re building your first microcommunity or scaling up your portfolio, the MODMAX blog is your go-to source for practical ideas, bold thinking, and on-the-ground wins.

Let’s talk. Book a consultation, tour our facility, or send us your project plans. We’ll show you what’s possible — and how fast we can make it real.